"Leadership is a constant commitment to excellence, constant self-improvement, and a constant concern for people."

– Pat Summitt

THE ART OF LEADERSHIP

Relentless Excellence

Pat Summitt’s Court-Tested Plan to Build Accountability, Sharpen Skills, and Win Together On and Off the Floor Every Single Day

Great teams aren’t born at tip-off; they’re built in quiet drills no one sees. As a leader you set the tempo. Show up early, prepared, focused on fundamentals. Consistency builds credibility, and credibility fuels trust. If you demand discipline, model it in your stance, tone, notes. Details like eye contact during drills speak volumes.

Accountability is our court press. Define clear roles, track effort, correct mistakes fast—never to embarrass, always to teach. Feedback is a gift wrapped in honesty, tied with respect. Call out what’s wrong, but shout what’s right louder. Celebrate hustle as loudly as wins. Practice ends only when the basics look automatic under fatigue; that’s when championship habits settle in.

Remember every athlete is a person first. Know their goals, fears, family stories. Push them hard because you believe in who they can become. Legacy isn’t banners; it’s the confidence they carry long after graduation. When they lead the next huddle with the same fire, you’ve won. Keep it bright daily Go

Run practice like game day: model discipline, give sharp feedback, spark belief. Leave the gym knowing team standards rose because you demanded more!

COMMERCIAL CONSTRUCTION

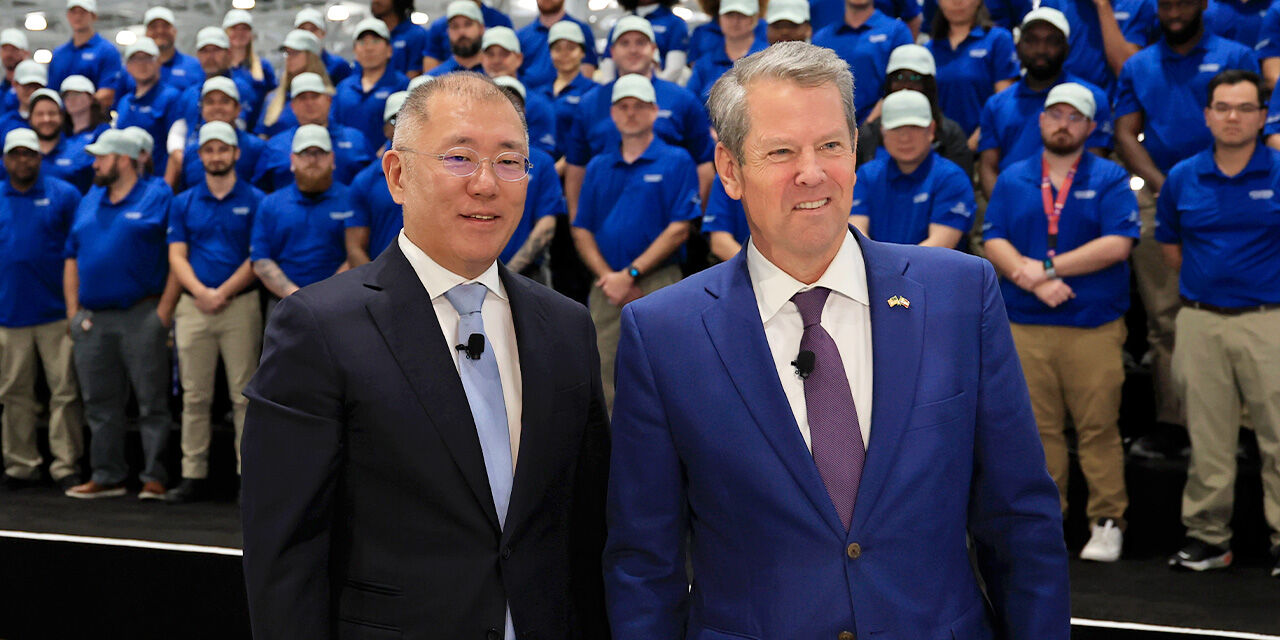

Hyundai EV Megaplant Opens – 30 Months After Start

Hyundai’s $7.6B Georgia Metaplant opens, unlocking 500k-vehicle EV capacity, 8,500 jobs and a solar-powered, AI-driven plant completed in record time

Hyundai Motor Group opened its $7.6 billion Metaplant America near Savannah on March 26, completing Georgia’s biggest project barely 30 months after ground-break. The 2,906-acre campus is already turning out Ioniq 5 and Ioniq 9 electric SUVs, kicking off annual capacity for 500,000 EV and hybrid models across Hyundai, Kia and Genesis.

The mile-long factory uses twice the automation of Hyundai’s older sites: AI carriers feed lines, robot dogs scan welds, and parking bots stage cars. A 5.2 MW solar lot powers logistics, and 21 hydrogen trucks shuttle parts. Staff will climb from 1,000 now to 8,500 by 2031 via an on-site training hub. Peak build manpower hit 12,000 and crews installed 300 miles of cable tray.

The ribbon-cut boosts the region by $4.6 billion a year and has lured $2.5 billion across 30 supplier deals. Hyundai next plans a $21 billion U.S. build-out, including a 2.7 million-ton steel mill beside the plant. Leaders tout the pace as a blueprint for IRA-era megaprojects.

INFRASTRUCTURE INDUSTRY

CT kicks off $137M I-95 West Haven bridge rebuild!

Lamont launches $137M two-span swap on I-95 West Haven: design-build widens lanes, adds bike path, keeps 250 day trains moving beneath without closure

Excavators rumbled onto I-95 in West Haven after Connecticut inked a $137 million deal with O&G/Aetna Bridge to swap the twin spans over Metro-North. Governor Ned Lamont hailed the start as “safety in action,” watching crews pound sheet piles during a pre-dawn rail outage. Traffic is already narrowed to 11-foot lanes and 50 mph.

The design-build team will erect prefabricated box-beam decks beside live traffic, slide lanes overnight, then chew out the 1970s girders. Upgrades add wider shoulders, sound walls, and a 12-ft bike-ped path, while cranes drop junk concrete into on-site crushers for reuse. Laser sensors on catenary poles warn if clearances pinch passing trains.

DOT says the job supports 800 union paychecks and should cut weekday backups 15 percent when new spans open in 2028. A fresh utility accord lets 250 trains rumble under the work at normal speed. Residents worry about overnight noise, but a hotline and stiff fines aim to keep drills polite. Work runs weekdays, dawn-dusk

RESIDENTIAL RESEARCH

Factory-Built Housing Boom Disrupts U.S. Market

Prefab builders race to meet demand as market hits $26.7B, zoning bills open single-family lots across nine states while investors snap up units fast

Factory-built housing blasted into the mainstream this spring: manufactured-home shipments sit 60 percent above 2014, and analysts value the North American prefab market at $26.7 billion for 2025. A steep mortgage gap steers buyers to quicker off-site builds while rental funds snap up units for yield.

Producers are scrambling. Clayton Homes posted record revenue, and Legacy Housing opened two Texas plants able to roll out 10,000 HUD-code homes a year. Avient joined Resia to 3-D print composite walls, slicing cycle times to 24 hours. Modular apartment shells logged by the trade group have doubled since last April.

Policy tailwinds are strong. Zoning bills in nine states would let factory homes on single-family lots, and new GSE guidance counts ADU rent toward loan approval. IBISWorld forecasts 5.8 percent annual growth through 2033, yet analysts warn capacity must scale quickly to dodge shortages next summer.

TOOLBOX TALK

The Importance of Safely Handling Asphalt Sealants on Construction Sites

Introduction

Good morning, Team! Today's toolbox talk covers the safe handling of asphalt sealants. These products protect paved surfaces but contain chemicals that can pose serious health risks if mishandled.

Why It Matters

Improper handling of sealants can lead to skin irritation, eye injuries, respiratory problems, or chemical burns. Safe practices prevent injuries and protect your health.

Strategies for Safe Handling

Wear Proper PPE:

Always use chemical-resistant gloves, eye protection, long sleeves, and respirators as needed.

Ensure Proper Ventilation:

Work in open, well-ventilated areas to reduce inhalation of harmful vapors.

Read Product Labels:

Follow instructions and warnings on sealant labels and safety data sheets (SDS).

Store and Handle Carefully:

Keep sealants tightly sealed in designated storage areas away from heat and flames.

Clean Spills Immediately:

Promptly contain and clean any sealant spills to prevent environmental hazards or slips.

Discussion Questions

Have you encountered hazards related to asphalt sealants on site?

What can we improve regarding our sealant safety practices?

Conclusion

Safe handling of asphalt sealants protects your health and safety. Always use proper PPE, ensure good ventilation, and handle responsibly.

Seal safely stay protected!